Liner Out-of-Track Service

Liner Out-of-Track Specialists — Diagnose, Reseat & Secure

When a vinyl liner bead pops out of the coping track, it can sag, wrinkle, or continue to pull away. Our Liner Out-of-Track Service identifies the cause—cold snaps, low water level, shrunken bead, track spread, or hardware issues— then warms, reseats, and locks the liner back in place to prevent repeat failures.

On-Site Assessment — find the root cause

We inspect bead condition, coping track, corners/steps, and water level to determine why the liner released and the best reseat strategy.

Targeted game planHeat-Assisted Reseat — liner-safe warming

Using controlled heat and support, we relax the vinyl and reseat the bead evenly without stretching or damaging the liner.

Gentle, controlled heatBead Lock Installed — hold it in place

We add continuous or spot bead-lock (liner lock) where needed to secure the bead and minimize future pop-outs.

Added mechanical gripTrack & Hardware — screws, gaps, corrosion

We check track alignment and fasteners; loose or spread sections are addressed and flagged if replacement is advisable.

Secure coping trackCorners, Steps & Bends — tricky zones

Tight radii and molded step areas get special handling so the bead seats uniformly and stays put.

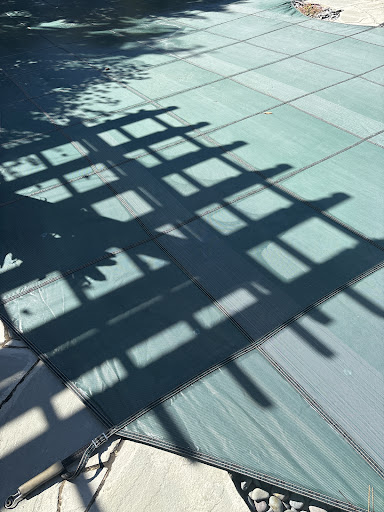

Precision reseatingWater Level Management — proper support

We adjust water level as needed to support the liner during reseat and advise on safe levels going forward.

Prevent future pop-outsAftercare Guidance — protect your reseat

Keep water at the recommended level, avoid draining, and allow warm weather to help the vinyl relax. We note any areas to monitor.

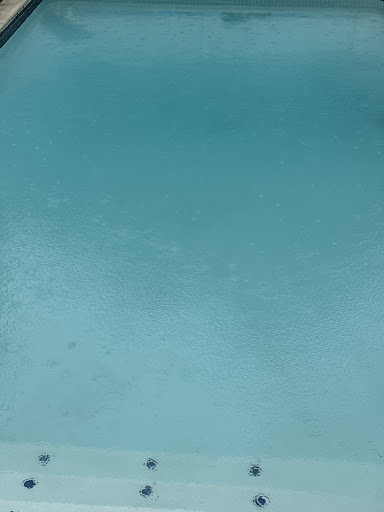

Simple care stepsSigns You Need This — act early

Bead hanging out of the track, gaps at corners, sagging above the waterline, wrinkles forming, or repeated seasonal pop-outs.

Stop damage early