LINER REPLACEMENT •

Pool Liner Replacement in

Empire Pools installs premium vinyl liners for pools — precision measuring, sub-base touch-ups, bead-track inspection,

and wrinkle-free vac set. We plan each replacement around debris and wind patterns near Merrick Road,

Bedford Avenue, Newbridge Road, Jerusalem Avenue, and Sunrise Highway

to keep debris out during set and fill—especially for homes closer to Mill Pond Park and the corridors leading toward the Bellmore LIRR Station.

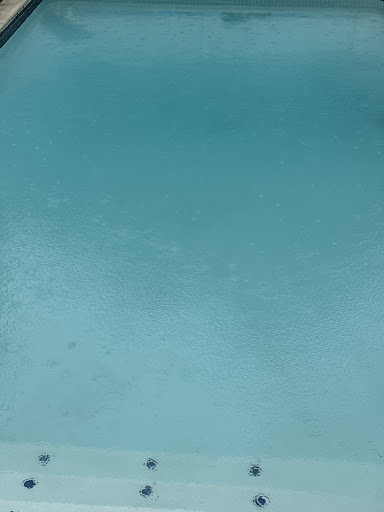

Our techs document measurements, track condition, and cut-ins so your new liner fits tight and opens crystal clear.

Every liner job starts with detail work that most companies rush: we verify wall height, radiuses, hopper/deep-end geometry,

and step/bench dimensions so the factory build matches your pool—not a “close enough” template. Before the liner goes in, we inspect the bead receiver,

coping, and track for brittleness or gaps that can cause the liner to pop out later, and we flag anything that should be corrected while the pool is empty.

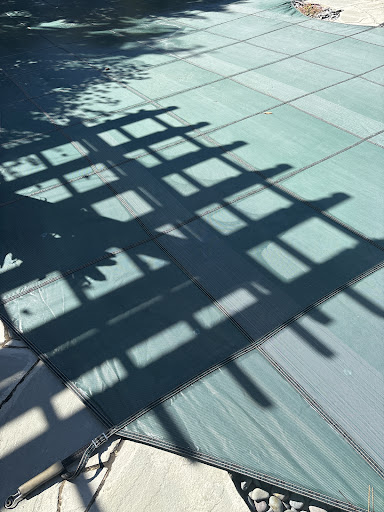

On install day we prep the floor so it’s smooth underfoot (patching divots and low spots, addressing vermiculite or base wear where needed),

then we use a controlled vac set and staged fill pace to pull the liner evenly into corners and seams.

If conditions change—wind picks up, leaves start dropping, or access is tight—we adjust our staging (hose routes, equipment placement, debris control)

so the liner stays clean during the most important part of the job: the first few inches of water and final alignment before cut-ins.

• Local Insight

Tuned for open-road gusts & tight access blocks

Busy corridors and open stretches can create quick breeze shifts that affect vac-set and seam alignment.

We stage equipment and manage fill pace so the liner sets smooth.

From stretches off Merrick Road to streets around Mill Pond Park and the area near the Bellmore LIRR Station,

we plan delivery, access, and hose routes to protect landscaping and speed the install.

What’s Included

- On-site measure (length/width/depths), wall height, and corner radii verification.

- Bead track inspection; replace brittle lock-in as needed (quoted on site).

- Sub-base touch-ups: floor trowel/patch, divot and wrinkle prevention.

- Liner hang and dual vac set for tight fit prior to filling.

- Cut-ins after water passes threshold: main drains, returns, lights, and skimmer.

- Hardware refresh (gaskets/faceplates/screws) as required by condition.

- Haul-away of old liner (available; quoted by weight/condition).

- Fill guidance to protect seams and prevent liner float; chemistry start-up.

- Note: Structural repairs, wall foam, vermiculite/base rebuild, and plumbing repairs are quoted if observed.

Why Choose Empire Pools

- expertise — manage wind, access, and fast weather swings during vac set.

- Wrinkle-free process with staged fill, seam alignment, and photo documentation.

- Transparent options: pattern choices, wall foam, step gaskets, and hardware refresh.

- Coordination for water delivery or hydrant permits when required (town rules vary).

- Clear scope & pricing before we begin — no surprises.

- Post-install check-in to confirm fit, fill progress, and chemistry balance.

Starting at $2,800 + tax

Local Reviews

★★★★★

“We’re a few blocks off Merrick Road and wanted zero wrinkles. The vac set was perfect and the liner pulled tight into every corner.” — K. M.,

★★★★★

“They spotted a bead track issue during measurement and explained it before install day. No upsell games—just the right fix.” — D. R.,

★★★★★

“Communication was on point. We’re near Bedford Avenue and access is tight—everything was staged clean and organized.” — S. P.,

★★★★★

“Old liner out, base touch-ups done, and the floor feels brand new underfoot. The seam lines are straight.” — J. T.,

★★★★★

“We’re close to Mill Pond Park and had leaves drop constantly—these guys kept the liner spotless during fill and cut-ins.” — A. L.,

Liner Replacement — FAQs

Do you replace pool liners throughout , NY?

Yes — we cover and nearby Nassau / Long Island areas. We typically schedule measurement first, then coordinate manufacturing and your install window.

What’s the difference between measuring and installation day?

Measurement is about geometry and fit: wall height, radiuses, hopper/deep-end shape, steps/benches, and track condition. Install day is liner hang, vac set, staged fill, and clean cut-ins once water reaches the safe threshold.

Can you address bead track or coping issues while the pool is empty?

Yes. We inspect the bead receiver/track during measurement and again before the liner goes in. If anything is brittle, cracked, or loose, we quote the correction before proceeding so you don’t get a liner “pop-out” later.

How do you prevent wrinkles during the fill?

We use a controlled vac set plus staged fill pacing so corners and seams seat evenly. We also correct low spots/divots in the base first—wrinkles usually come from base imperfections or rushing the first few inches of water.

What can delay a liner install in ?

Most delays come from unexpected base repairs after removal, water logistics (flow/source), or weather/wind on install day. We stage and schedule to reduce risk, but we won’t “force” an install if conditions threaten the finish.

What helps you quote faster?

Pool shape, approximate dimensions, wall height, step/bench details, and a few photos (wide pool shot + equipment pad + bead track close-up) help us price accurately and schedule measurement faster.